High Quality Hthp Textile Dyeing Machine for Cotton Nylon Polyester Chemical Fiber Acrylic Zipper Tape Hank Yarn

Basic Info

| Model NO. | HT23003DM19 |

| Automatic Grade | Automatic |

| Working Width | 1.5m |

| Material | Cotton Fabric |

| Voltage | 380V |

| Load Capacity | 500-1000kg |

| Certification | ISO9001: 2000 |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Heat | Electricity Steam |

| Compressed Air Pressure | 0.6MPa |

| PLC | Is Avariable After Confirmation |

| Liquor Ratio | 1:3-4 : 1:6-8 : 1:8-10 |

| Way of Installation | Fixed |

| Transducer | Yes |

| Body Material | Stainless Steel |

| Maximum Temperature | 140 |

| Machinery Test Report | Provided |

| Core Components | PLC, Motor, Pump |

| Marketing Type | Ordinary Product |

| Feature | Critical Cleaning / Residue Free |

| Cleaning Type | Immersion / Soak |

| Fuel | Electric |

| Machine Type | Industrial Machine |

| Transport Package | Wooden Cases |

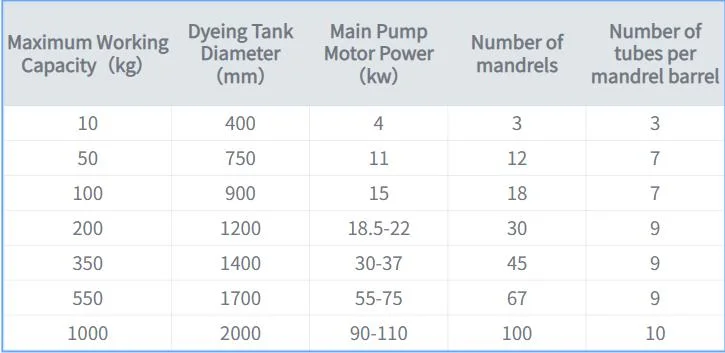

| Specification | from 1kg to 1000kg capacity |

| Trademark | HARTAUN |

| Origin | Jiangsu, China |

| HS Code | 8451400000 |

| Production Capacity | 5000 Pieces/Year |

Product Description

| High Quality HTHP Textile Dyeing Machine for Cotton Nylon Polyester Chemical Fiber Acrylic Zipper Tape Hank Yarn |

1.Adapt innovative centrifugal pump, with the advantage of high performance, high efficiency, low energy consumption, long service life and convenient maintenance.

2.Newly developed buit-in spiral heating tube to improve heat exchange efficiency.

3.The new automatic liquid-flow reversing device,combined with the innovative centrifugal pump, shortens the distance between the pump and the yarn carrier, reduces the pressure loss and the liquor ratio.

4.Pressure dewatering: pressure drain the strong sewage of the yarn,reduce the water consumption during rinsing and improve the working environment.

5.Low liquor ratio dyeing: Saves dyes, chemical additives, steam, electricitand water consumption.(1:4-1:6).

6.Variable loading: Special designed fast de-load carrier, with the intelligent water in control, it can reduce the water consumption.

7.Special pulse flow dyeing technology: adopt the advanced pulse flow power- saving system, it can constantly change the dyeing liquor pressure for the yarn, increase the level dyeing property, reduce the powe consumption.

1.All metal parts of the dyeing machine contact withing the dye liquor are made of high quality anti-corrosion stainless steel 316L.

2.Frequency controlled high efficiency unique centrifugal pump.

3.High efficiency inside heat exchanger.

4.Vertical dyeing tank, lid opening mechanism combined with cylinder or counterweight switch system, and safety interlocking system.

5.Dosing tank with ration feeding system.

6.Pressurized air for main tank (Air pad type).

7.High accurate pressure transmitter to control the liquor level

8.Multi-function intelligent computer and PLC ,control the dosing, water inletting,draining, temperature rising, decreasing and keeping, and the rising etc.

9.High temperature drain.

10.Ration dosing system.

11.Secondary water feeding and draining.

12.De-loading cones other accessories.

Q1.Can you provide OEM service?we can provide OEM service. It will depend on your requests,your logo will be customized on our products.Q2.How many days about delivery time?15-20 days after TT deposit.Q3.What is the packing? General machines are with vacuum packing. Particular machine are packing with vacuum and wooden case. Container loads as per the machine size.Q4. What information may contain in my inquiry? Your request your machine's embroidery area /needle number /head number/head interval/other function need.Q5. Do you test all your goods before delivery?Yes, we have 100% test before deliveryQ6.How to insatll and use the embroidery machine? We have the English teaching manual and videos;The videos about every step of machine Disassembly, assembly, operation.Q7: How do you make our business long-term and good relationship?1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them.